Viewpoint Vista Inventory Scanning

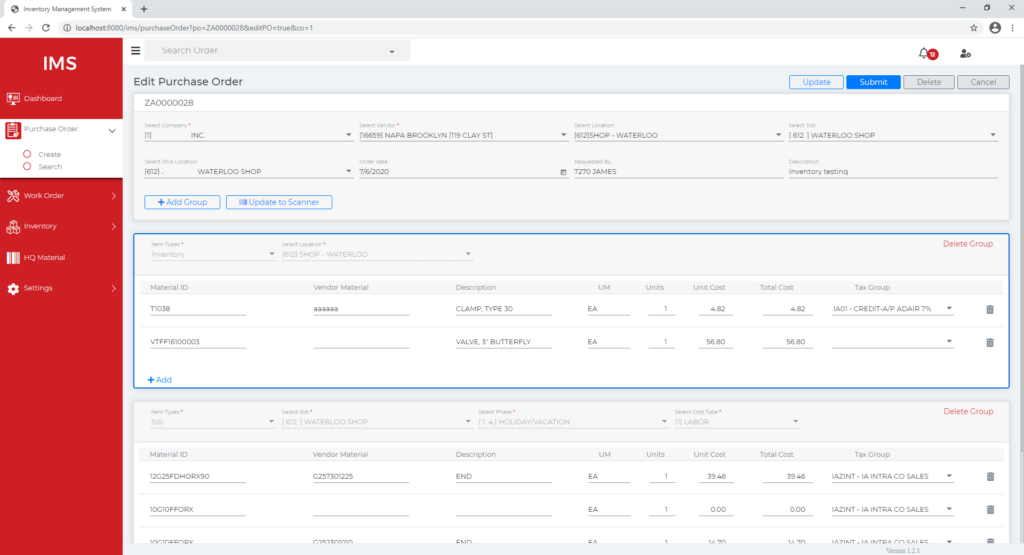

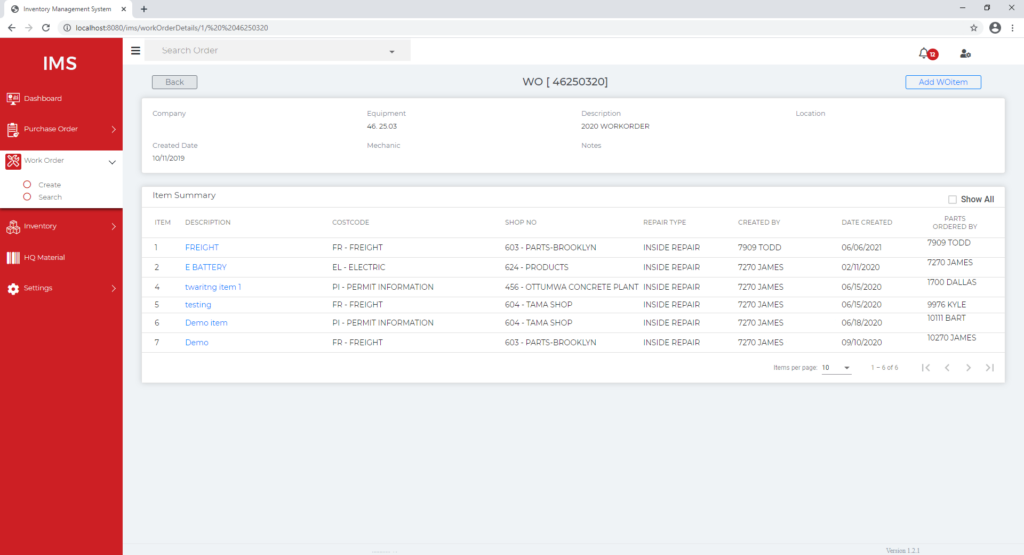

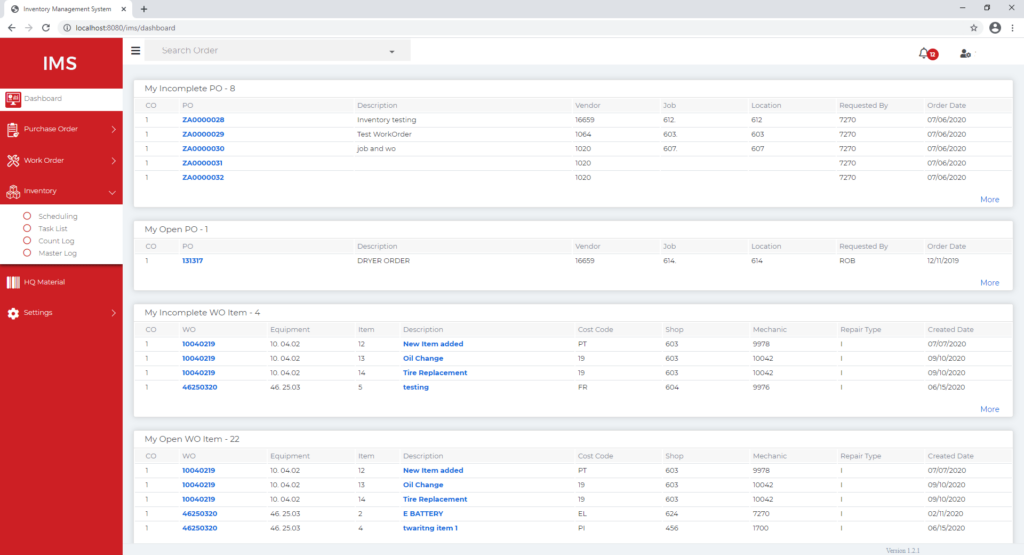

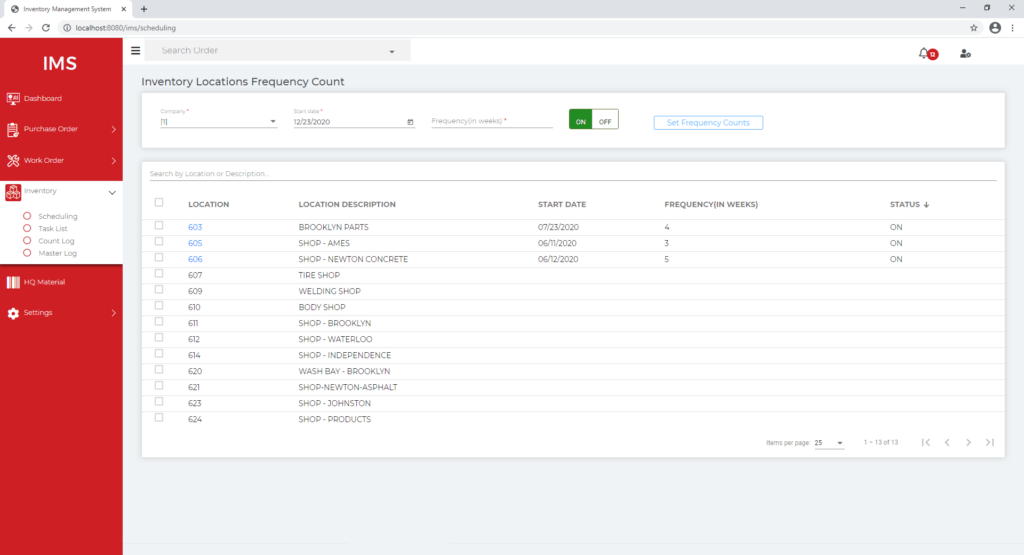

A major Illinois-based construction company specializing in bridge projects was grappling with the management of parts for over 1,000 equipment pieces across multiple warehouses. Their manual, spreadsheet-based tracking system and the direct expensing of parts to equipment created inefficiencies. The company relied on Viewpoint Vista and their ERP system, which lacked comprehensive inventory management features, causing operational difficulties, particularly with large part volumes. In response, the company turned to Nobious Business Automation for a solution. Nobious introduced a tightly integrated inventory management system that incorporated barcode scanning technology. This system streamlined inventory reception and location tracking, providing real-time insights into stock levels. Additionally, a user-friendly kiosk was established for employees to quickly locate and check part availability. Nobious also optimized the company’s accounting processes to align them with efficient inventory management practices. The result is a highly organized and automated warehouse, enhancing the ease of locating and utilizing parts, ultimately improving operational efficiency and accuracy.

Viewpoint Vista Inventory Scanning Read More »