WORK ORDER AUTOMATION

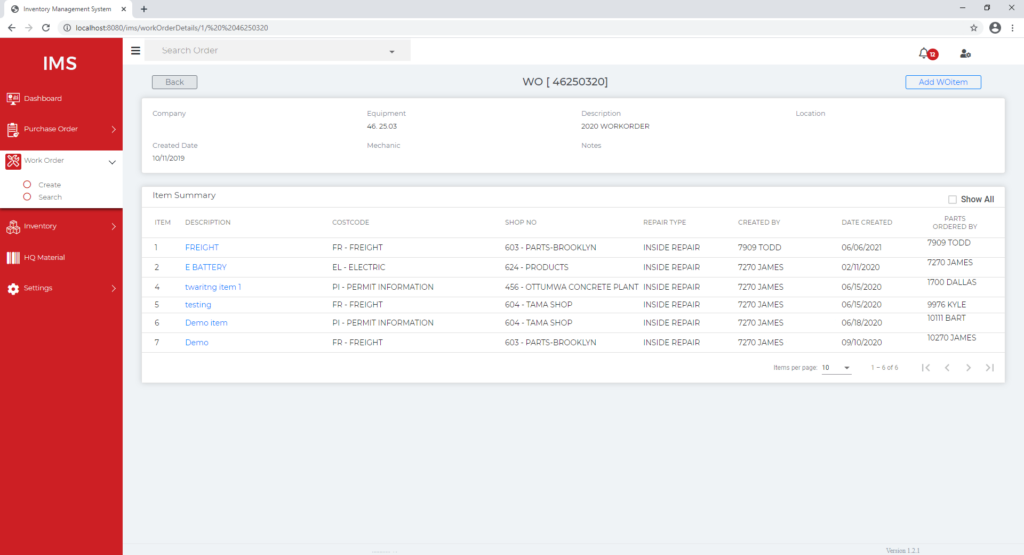

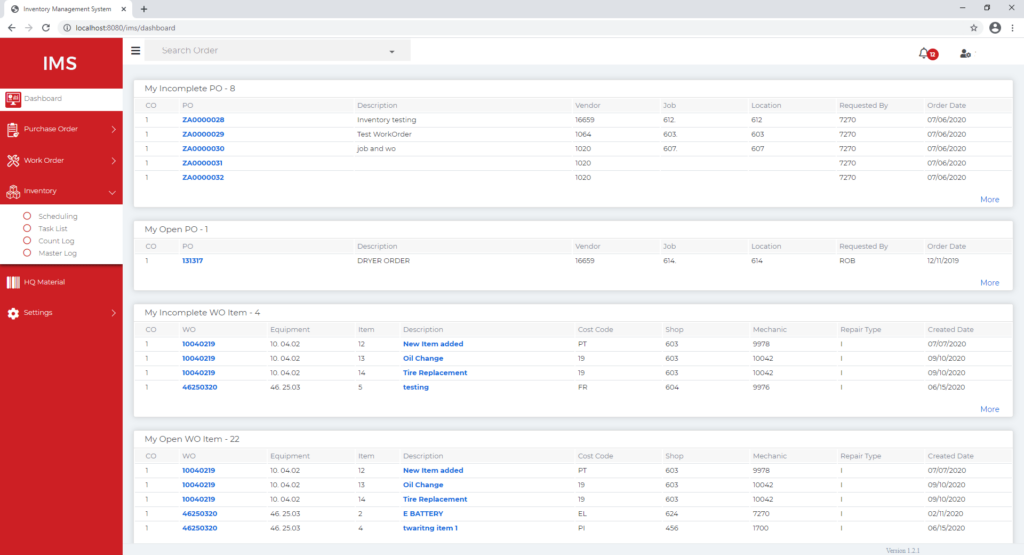

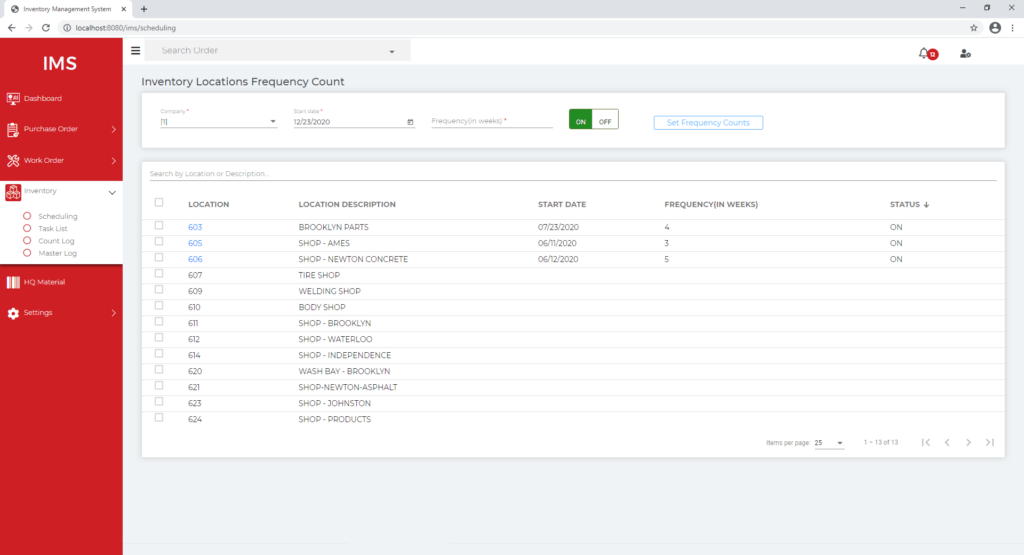

Our client’s parts department needed a way for employees to quickly enter work orders and order parts. Their ERP system (Viewpoint) required an expensive new subscription in order to give access to their mechanics, technicians and other members of the field team. Instead of paying these high fees forever, they decided to build a solution themselves. They engaged Nobious, and we built a custom web and mobile based add-on that tightly integrated with their ERP system. Now, mechanics can order parts using their phone from the site of the break down, warehouse teams can scan any barcode, and they have no monthly fees since they own the software.

WORK ORDER AUTOMATION Read More »