Why Lifecycle Tracking Matters

Construction companies invest heavily in tools, yet many struggle to track where those tools are, who is using them, or whether they are overdue for service. Most firms lose thousands of dollars each year through shrinkage, misplaced tools, duplicate purchases, and unplanned downtime. Studies show that contractors with more than half a million dollars in tools often lose ten to twenty percent of that value annually.

These losses happen because the full lifecycle of each tool is not clearly captured. Every tool moves through predictable stages such as acquisition, assignment, jobsite use, maintenance, and retirement. Without structure, tools drift through these stages with little documentation. Smart barcoding creates consistent visibility so each step in the lifecycle becomes organized, traceable, and measurable.

What Lifecycle Tracking Looks Like with Barcodes

Acquisition and Tagging

The lifecycle begins at receiving. When a tool arrives from a vendor, applying a barcode creates a digital asset record that stores dozen of datapoints: including warranty dates, purchase costs, and future maintenance intervals. This prevents untagged tools from entering circulation and disappearing before anyone knows they exist.

Assignment

Barcode scanning allows teams to check tools in and out within seconds. This replaces handwritten logs or verbal tracking and establishes clear ownership. Each scan ties the tool to an employee, crew, job, or storage location. Loss rates drop significantly when accountability improves.

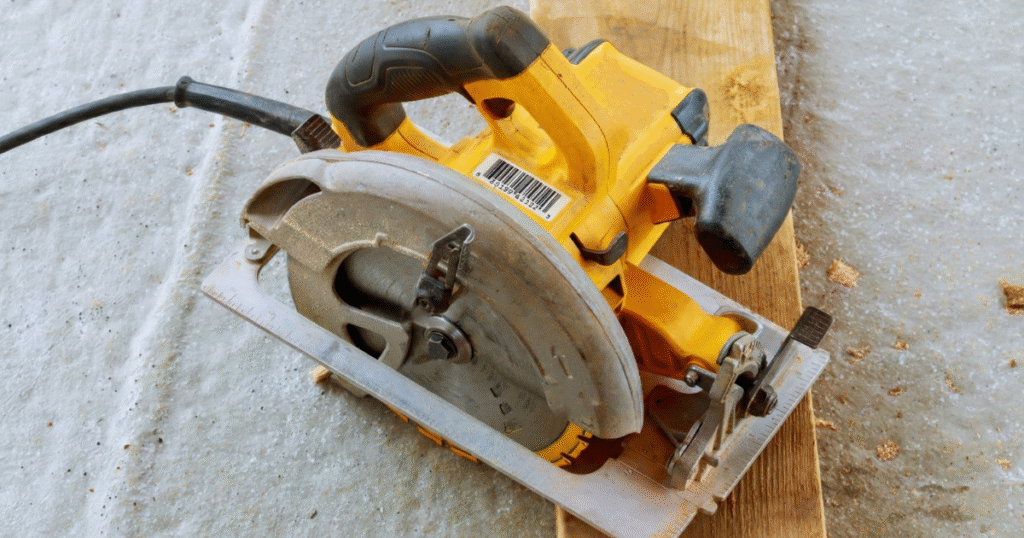

Movement on Jobsites

Tools move constantly between the warehouse, pickups, trailers, and active job areas. This is where most tools go missing. Barcode scanning captures each movement and shows where tools are located in real time. It eliminates the “black hole zones” where tools vanish for days or weeks. Foremen and warehouse staff gain a shared view of what is available and where it is positioned.

Maintenance and Calibration

Many construction tools require routine inspections or calibration. Without a structured system, maintenance is often missed or handled reactively after equipment fails. With lifecycle barcoding, service intervals are linked to actual usage and time in the field. Tools receive maintenance when it is due, not when someone finally notices a problem. This reduces downtime, rental costs, safety issues, and project disruptions.

Retirement and Depreciation

As tools age, their repair frequency and cost patterns become clear. Lifecycle records show how often tools break, how much they cost to maintain, and when they reach the point where replacement is more cost-effective. Barcoding also supports accurate depreciation and asset reporting for accounting teams.

Where Construction Firms Lose the Most Money

Lifecycle tracking solves several major problem areas.

Loss and Shrinkage

When tools are not assigned to a responsible person or job, they are more likely to disappear. Barcode-based accountability has been shown to reduce shrinkage significantly across industries, with some reports showing reductions up to 50 percent.

Misallocation

Duplicate tool purchases often occur because teams do not know what is already available. Real-time visibility prevents unnecessary orders and lowers procurement spend.

Downtime

Unplanned downtime is expensive. Crews cannot work effectively when essential tools are lost, broken, or overdue for service. Lifecycle tracking ensures tools remain ready for use and available at the right time.

Compliance and Documentation

Calibrated tools and safety equipment require reliable documentation during audits or inspections. Barcode logs provide instant records of maintenance history and tool availability.

How Lifecycle Barcoding Connects to Viewpoint Vista

For construction firms that rely on Viewpoint Vista, lifecycle tracking becomes even more powerful. Each scan can connect to job codes, cost centers, and work activities. This creates accurate job cost visibility and reduces manual data entry. It helps teams understand where tools are being used, how often they move between sites, and what maintenance costs belong to each project.

Barcode-driven lifecycle data also supports better forecasting. Historical movement and maintenance patterns help companies determine what tools they need to purchase, what to retire, and how to redistribute assets across active jobs.

Tools represent a major investment for construction companies, and managing them effectively directly impacts profit margins. Lifecycle tracking supported by barcoding increases accountability, reduces waste, prevents downtime, and provides accurate records across the entire company. When connected with systems like Viewpoint Vista, lifecycle visibility becomes a competitive advantage for operations and project management teams.