The 2026 construction landscape is a battle of efficiency. With the industry facing a massive deficit of over 439,000 workers, you can no longer simply “hire your way” out of a backlog. To stay competitive, you need to stop the silent erosion of your margins caused by lost tools, missing materials, messy paperwork, and disconnected data.

Here are the five high-impact operational trends that will define successful firms in 2026.

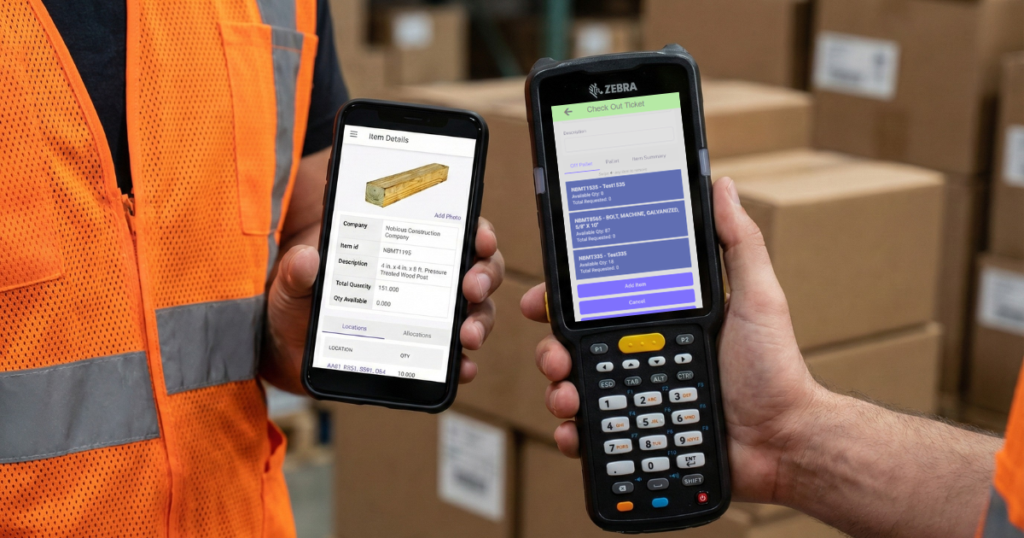

1. The Mobile Warehouse (Conex-to-Cloud)

In 2026, a messy jobsite is a costly jobsite. Every trailer, Conex box, and storage rack becomes a “mobile warehouse” the moment materials are delivered.

- The Trend: Crews are using handheld scanners or their phone to track direct-to-jobsite deliveries in real-time.

- The Goal: Eliminate the black hole zones where expensive materials vanish for weeks, only to be mistakenly reordered.

2. Predictive Tool Lifecycle Management

Misplaced, broken or even stolen tools are more than a minor annoyance; they represent a significant drain on your annual profit.

- The Trend: Firms are moving toward Lifecycle Tracking, using barcode scans to monitor every tool from purchase to retirement.

- The Goal: By tracking repair costs against replacement value directly in your ERP, you can decide exactly when a tool becomes a liability instead of an asset.

3. Rich Text Messaging Based Audit-Ready Safety

Safety documentation shouldn’t live on a coffee-stained clipboard in the back of a truck. Regulatory compliance in 2026 demands total traceability.

- The Trend: SMS-based learning allows employees to receive safety materials and quizzes directly on their phones via text.

- The Goal: Accurate transcripts due to Crew led tracking automatically populate your HR training modules, keeping your team audit-ready at all times.

4. Labor-First Automation

Your high-value superintendents should be building, not acting as data entry clerks. In a tight labor market, tech-enablement is a primary strategy for retaining top talent.

- The Trend: Process Automation captures activity exactly where and when it happens, so data is entered once and used throughout the entire organization.

- The Goal: Eliminate the manual data entry that wastes over five hours of your field leaders’ time every week.

What’s the cost of poor technology? In 2026, you risk losing talented people to companies that provide cutting-edge tools, which enable them to be more successful and provide more value.

5. The Zero-Sync Real-Time Extension

If your field data has to synchronize overnight, you are already behind. In 2026, the operational mandate is a Real-Time Extension of your ERP, like Viewpoint Vista or Spectrum.

- The Goal: In the field, when a worker scans an item to the job, job costing updates in the office instantly: not hours later.

- The Result: Project managers gain a clear, daily view of their actual costs, allowing them to protect margins against 2026 material price swings.

Manual tracking works, but it remains the primary obstacle to true efficiency. Nobious is the only inventory system purpose-built for Viewpoint Vista users to solve these exact 2026 challenges.

By using barcode and QR scanning, your team can track locations, equipment, and labor in seconds, without ever needing a synchronization process. It turns your complex field workflows into a process that works effortlessly.