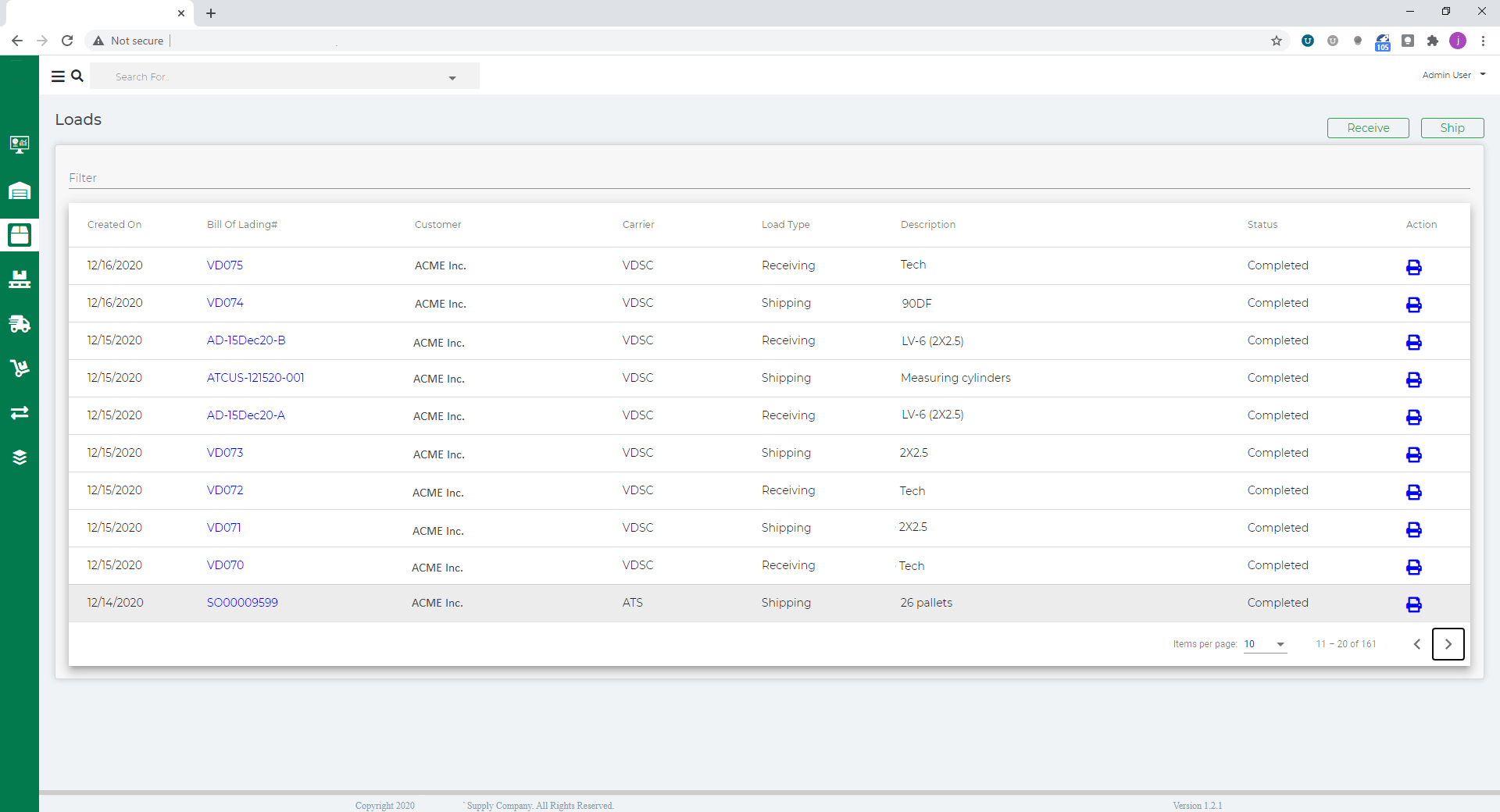

Our client built a 122,500 square foot warehouse to store inventory for their customers. They needed a way to track product coming in and out of the warehouse. The solution also needed to automate billing. They looked at pre-packaged warehouse solutions but they were expensive, required significant configuration and setup, and didn't manage billing. They worked with Nobious to build a system customized specifically for their business. The new Inventory Management System allowed warehouse employees to identify the exact location of any product in real-time. Using advanced barcoding technologies, the system tracks all loads coming in and going out while fully automating the monthly billing process. Now the small warehouse team can easily manage up to 16,000 pallets at any given time.

About The Author

Related Blogs

ADMINISTRATION

Our client built a 122,500 square foot warehouse to store inventory for their customers. They needed a way to track product coming in and out of the warehouse. The solution also needed to automate billing. They looked at pre-packaged warehouse solutions but they were expensive, required significant configuration and setup, and didn't manage billing. They worked with Nobious to build a system…

TRAVEL REQUEST APPROVAL

Our client built a 122,500 square foot warehouse to store inventory for their customers. They needed a way to track product coming in and out of the warehouse. The solution also needed to automate billing. They looked at pre-packaged warehouse solutions but they were expensive, required significant configuration and setup, and didn't manage billing. They worked with Nobious to build a system…